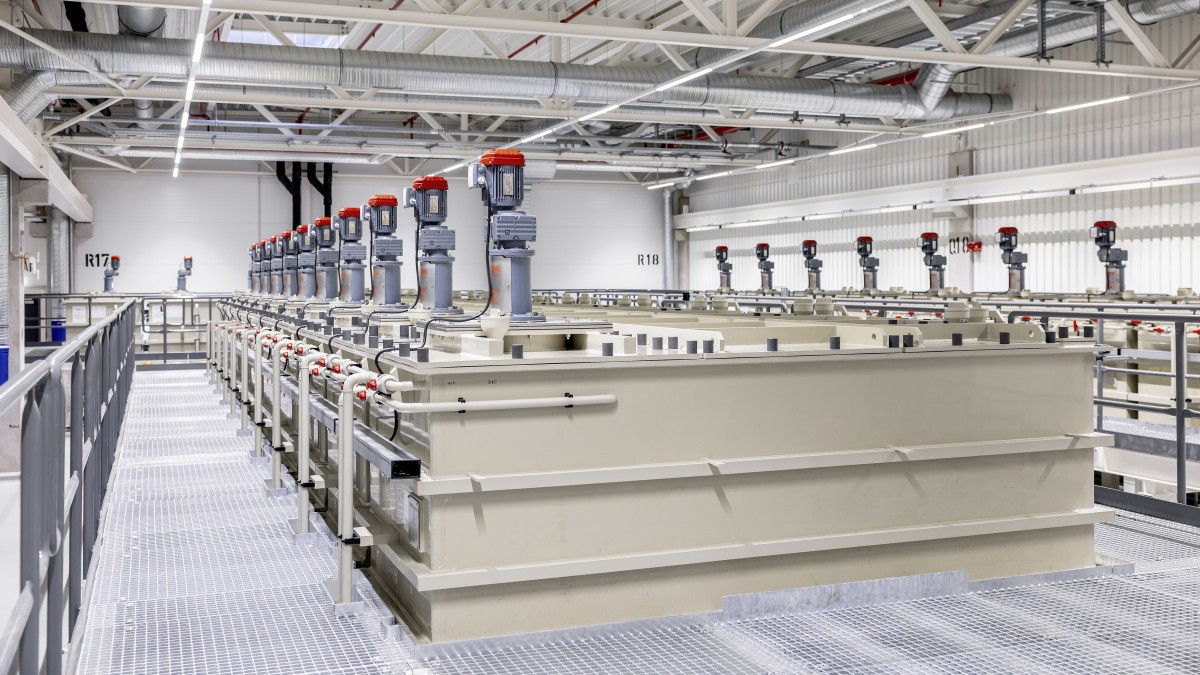

Mercedes opens its first battery recycling plant

Today Mercedes has proudly announced that it's opened its first battery recycling plant. It's located in Kuppenheim in southern Germany, and will operate with an expected recovery rate of more than 96% thanks to its mechanical-hydrometallurgical process. It's net CO2-neutral too thanks to its roof being equipped with a photovoltaic system and it makes Mercedes the first car manufacturer in the world to close the battery recycling loop with its own facility, one that cost tens of millions of euros.

The plan is for this plant to generate enough recycled materials to produce more than 50,000 new battery modules each year. Lithium, nickel, and cobalt can be recovered to be used in new batteries for future Mercedes cars.

Mercedes' partner for this plant is Primobius, a joint venture between German engineering group SMS and Australian process technology developer Neometals. Aside from Mercedes' own investment, the plant is also receiving federal funding in Germany as part of a project with three German universities, which are looking at the entire process chain for recycling, including logistics and reintegration concepts.

The plant has an annual capacity of 2,500 tonnes, and it could be scaled up in the medium to long term, if the need arises.

Reader comments

- Anonymous

- 0Cg

"The plant has an annual capacity of 2,500 tonnes, and it could be scaled up in the medium to long term, if the need arises." 2,500 tones is a very small amount. I found that Tesla Model S battery with 85kWh capacity weighs 540kg. So...

- Funny guy

- ix7

Basically, bring in new batteries and quietly install them in the old housing, seal them and keep the charade going until either A) actually recyclable Lithium batteries are made or B) shut down the program and blame the lack of ev sales.

Facebook

Twitter

Instagram

RSS

Settings

Log in I forgot my password Sign up