Polestar 4 has the lowest carbon impact of all Polestar vehicles at launch

The Polestar 4, unveiled back in April for the Chinese market, is the vehicle with the lowest carbon impact at launch from the entire Polestar lineup. The brand just published its Life Cycle Assessment (LCA) for it, and the results are great.

The Polestar 4 is made at Geely's SEA factory in Hangzhou Bay, China. This plant combines green electricity that carries the I-REC hydro power certificate with photovoltaic electricity from its roof.

The climate impact is further reduced during production by employing low-carbon aluminum from smelters using hydropower electricity, as the data regarding the share of recycled aluminum has been included in an LCA for the first time.

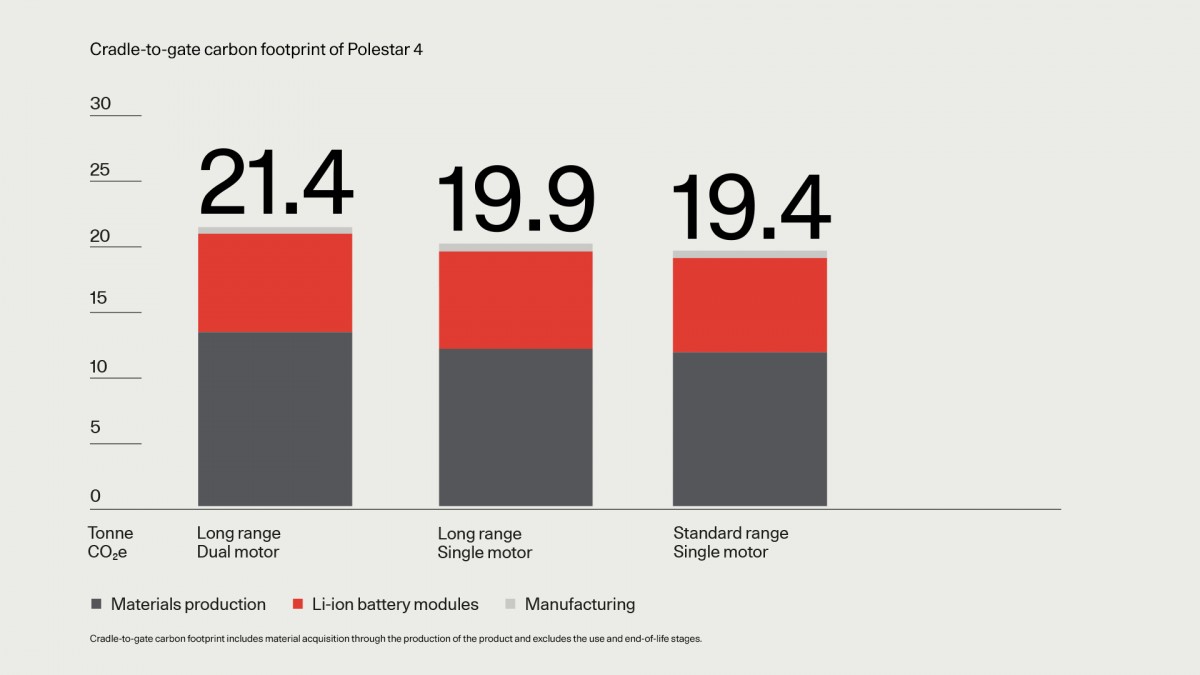

The Polestar 4 Standard range Single motor has a carbon footprint of 19.4 tCO2e. The Long range Single motor version takes that to 19.9 tCO2e, while the Long range Dual motor reaches 21.4 tCO2e.

The battery modules have the highest share of the carbon footprint of materials production and refining at 36-40%, followed by aluminum which represents about 23-24%, and steel and iron at 20%.

To celebrate the news, Fredrika Klarén, Head of Sustainability at Polestar, said:

To support our net zero goal, we set carbon budgets for all our cars. Throughout the product development of Polestar 4, its carbon budget has influenced everything from material choices to factory energy sources. Sharing the LCA enables us to show that we can strive for net zero – one ton of CO2e at a time.

Reader comments

- Anonymous

- Fht

It would be nice to have the manufacturing carbon footprint of all electric cars. It’s pretty hard to calculate but still. It’s odd that most of the new BEVs are big SUVs which severely lowers the positive impact they could have (vs ice cars). ...

Facebook

Twitter

Instagram

RSS

Settings

Log in I forgot my password Sign up