BMW breaks the ground on $700 million EV battery factory in South Carolina

Today in Woodruff, South Carolina, the BMW Group marked a significant milestone towards their goal of electric vehicle production in the United States. They ceremoniously broke ground on a new high-voltage battery assembly plant. Once operational, the BMW Group Plant Woodruff will be tasked with producing sixth-generation batteries, supplying the fully electric vehicles manufactured at the nearby BMW facility in Spartanburg. The project promises to create more than 300 jobs at the Woodruff site, with potential for growth.

Ilka Horstmeier, a board member of BMW AG responsible for People and Real Estate, stated, "We're steering the BMW Group towards an electric future. Our forthcoming battery assembly plant in Woodruff is pivotal to our electrification strategy in the U.S." Horstmeier further emphasized the company's commitment to its associates and their adaptation to this new era, with plans for a new Technical Training Center at the Spartanburg plant.

Future of BMW will depend on the new US facility

Future of BMW will depend on the new US facility

"This groundbreaking marks a fresh chapter at Plant Spartanburg as we gear up to manufacture fully electric BMW X models for a global market," said Robert Engelhorn, president and CEO of BMW Manufacturing in Spartanburg. Engelhorn assured that the new Plant Woodruff would embody the apex of sustainability, flexibility, and digitalization.

In October 2022, the BMW Group revealed a $1.7 billion investment plan for its U.S. operations, dedicating $1.0 billion to prepare the Spartanburg plant for fully electric vehicle production and allocating $700 million towards building the new high-voltage battery assembly plant in Woodruff. The new Woodruff facility, encompassing approximately 100 acres, will house a technology building and several support structures, including a cafeteria, fire department, and energy center.

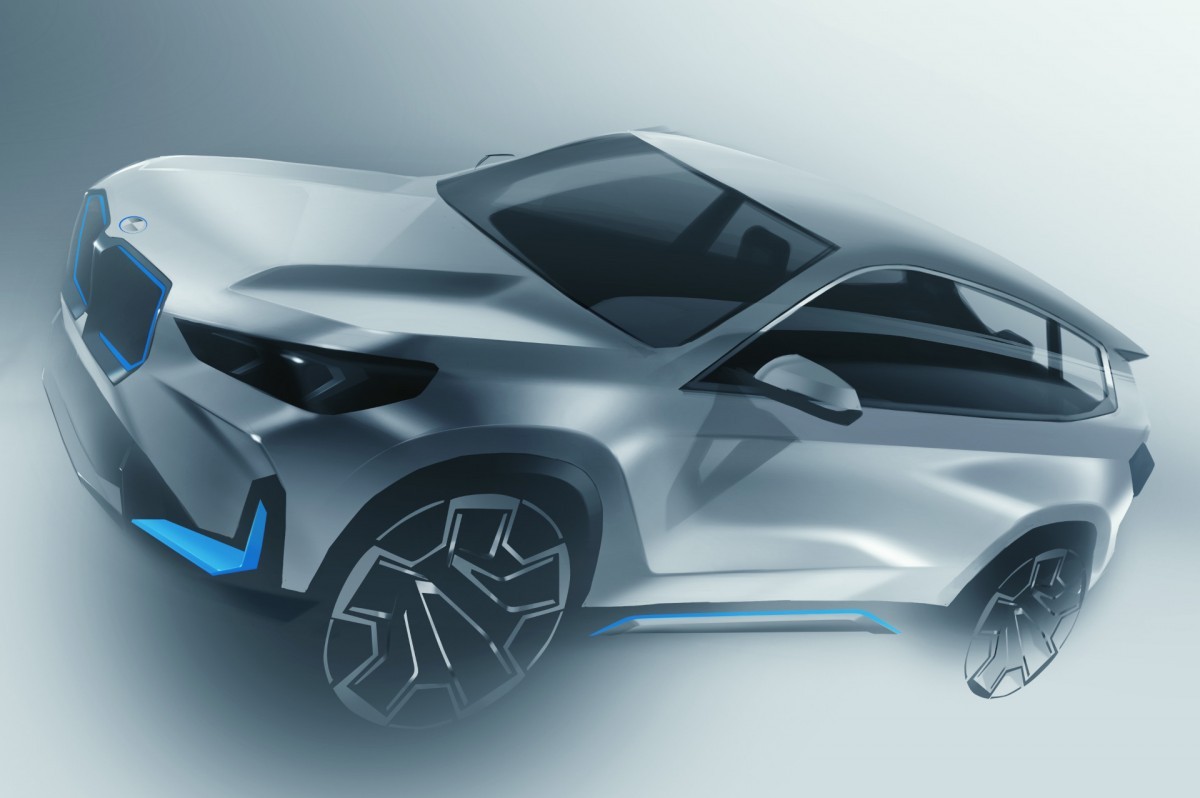

One of new electric BMWs

One of new electric BMWs

Markus Fallböhmer, Senior Vice President of Battery Production at BMW AG, discussed the company's 'local for local' approach, where the proximity between battery and vehicle production is a key strategic element. This approach will include sourcing battery cells from partner company AESC, which is in the process of constructing a 30 GWh battery cell factory in Florence, South Carolina. These new cells, specifically designed for BMW's sixth-generation eDrive technology, are expected to increase energy density by more than 20% and enhance charging speed and range by up to 30%.

Emphasizing its commitment to sustainability, the BMW Group plans to minimize carbon footprint and resource consumption during production. Battery cell manufacturers will use a certain percentage of secondary material, essentially recycled raw materials, in the production process. Combined with a commitment to using only renewable energy for battery cell production, this strategy could reduce the carbon footprint of battery cell production by up to 60%.

High environmental standards are set for the Woodruff plant, which will operate entirely without fossil fuels and use 100% green electricity. The company has set ambitious goals, aiming to reduce CO2 emissions in its global production network by 80% by 2030 compared to 2019 levels.

The BMW Group has a rich history in South Carolina, having invested about $12.4 billion in its operations there since 1992. The Spartanburg plant, BMW's largest worldwide, produces more than 1,500 vehicles daily and employs over 11,000 people. The new investment reaffirms the BMW Group's ongoing commitment to the U.S., where it operates nearly 30 locations in 12 different states, offering direct and indirect support to more than 120,000 jobs across the nation.

Facebook

Twitter

Instagram

RSS

Settings

Log in I forgot my password Sign up