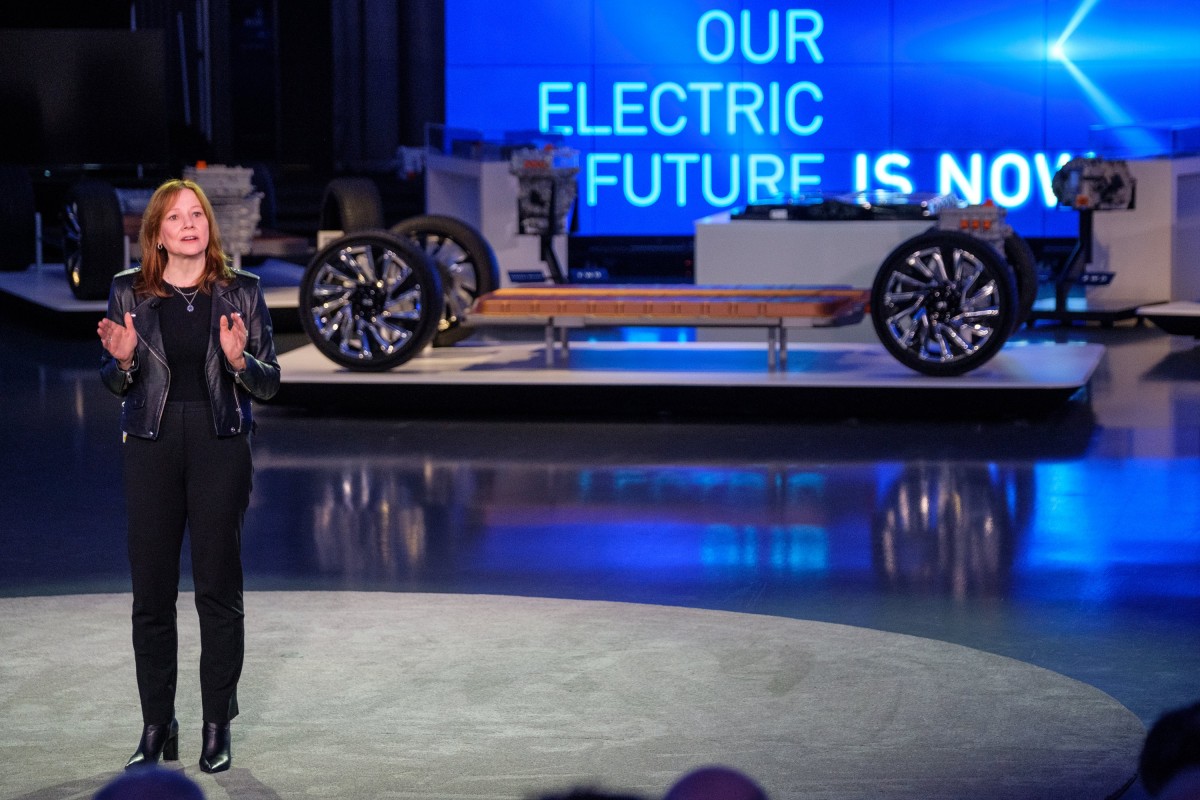

GM challenges Tesla’s dominance in EV battery production

General Motors is making big moves in the world of electric vehicles. The latest reports show that GM is now producing more battery cells in the United States than Tesla. This makes GM not only a major car maker but also a significant player in the battery industry.

The lithium-ion battery is a key part of electric cars, similar to how gasoline engines power traditional vehicles. Unlike developing new gas engines, which can be costly and time-consuming, a good electric car battery design is universal and can be used in many different models. This can help companies save money and develop new EVs more quickly. GM seems to be using this strategy effectively.

GM's commitment to electric vehicles is clear from its large battery factories. One of these, located near Nashville, Tennessee, cost $2.3 billion to build and is as big as five football fields. This factory runs non-stop, producing about 5,000 battery cells every hour. Another large factory in Lordstown, Ohio, also contributes to GM's growing battery production. These two plants are a partnership between GM and a South Korean battery company, LG Energy Solution. Together, they supply batteries for popular EVs like the Chevrolet Equinox EV and the Cadillac Lyriq.

The increasing popularity of GM's electric cars is partly due to their price. Kurt Kelty, who used to be in charge of batteries at Tesla and now holds a similar position at GM, stated that GM significantly reduced its battery costs last year by $60 per kWh. The company wants to cut costs by another $30 per kWh this year by making more batteries and improving its production process. If GM achieves this, their battery costs could be around $100 per kWh, a 50% drop compared to 2023. This could even put them in a position to sell batteries for less than Tesla. For comparison, the average battery cost in China is $94 per kWh.

Even with these cost reductions, the battery packs for cars like the Chevrolet Blazer EV and Equinox EV still cost about $13,000. To lower costs further and improve their EVs, GM is planning to use a different type of battery cell called a prismatic cell. These cells are shaped like rectangular blocks and can fit together more efficiently, saving space and potentially increasing the driving range of electric cars.

GM has partnered with Samsung SDI in a $3.5 billion project to build a factory in Indiana that will produce these prismatic cells. While this factory was initially expected to start production next year, it is now delayed until 2027.

Reader comments

- Anonymous

- 3Ts

"The lithium-ion battery is a key part of electric cars, similar to how gasoline engines power traditional vehicles. Unlike developing new gas engines, which can be costly and time-consuming, a good electric car battery design is universal and c...

Facebook

Twitter

Instagram

RSS

Settings

Log in I forgot my password Sign up