Toyota unveils ambitious new EV production facility

Toyota has taken an ambitious leap into the future of electric vehicles. After sitting on the sidelines of the EV revolution, and at times dismissing it at large, the company finally realized it may be on the wrong side of the fence. The recent unveiling of its state-of-the-art EV production line in Japan paints a vivid picture of a company trying to redefine itself in the electric age.

The giant's new battery electric vehicle production line boasts some truly intriguing technologies. And if it's a reflection of what's to come, it could spell a transformative period for the once-automotive leader.

At the heart of Toyota's newfound fervor for EVs is its giga-casting technology, showcased at the Myochi plant. Giga casting, for those not deep in the automotive rabbit hole, uses massive single-piece castings for critical vehicle structures and we have Tesla to credit for this approach. This method not only shaves off considerable weight but also bolsters structural integrity and dramatically simplifies the production process. Considering Toyota's announcement that mold change lead times could drop from a day to a mere 20 minutes, one can't help but raise an eyebrow in genuine awe. Or is it skepticism?

Let's not forget Toyota's reputation for crafting technologies. This behemoth isn't new to the casting game; it's been honing its techniques from the days of engine manufacturing. However, the company's recent pivot towards proprietary analysis technology to refine casting quality certainly seems like a move to curb production defects. A noble move indeed.

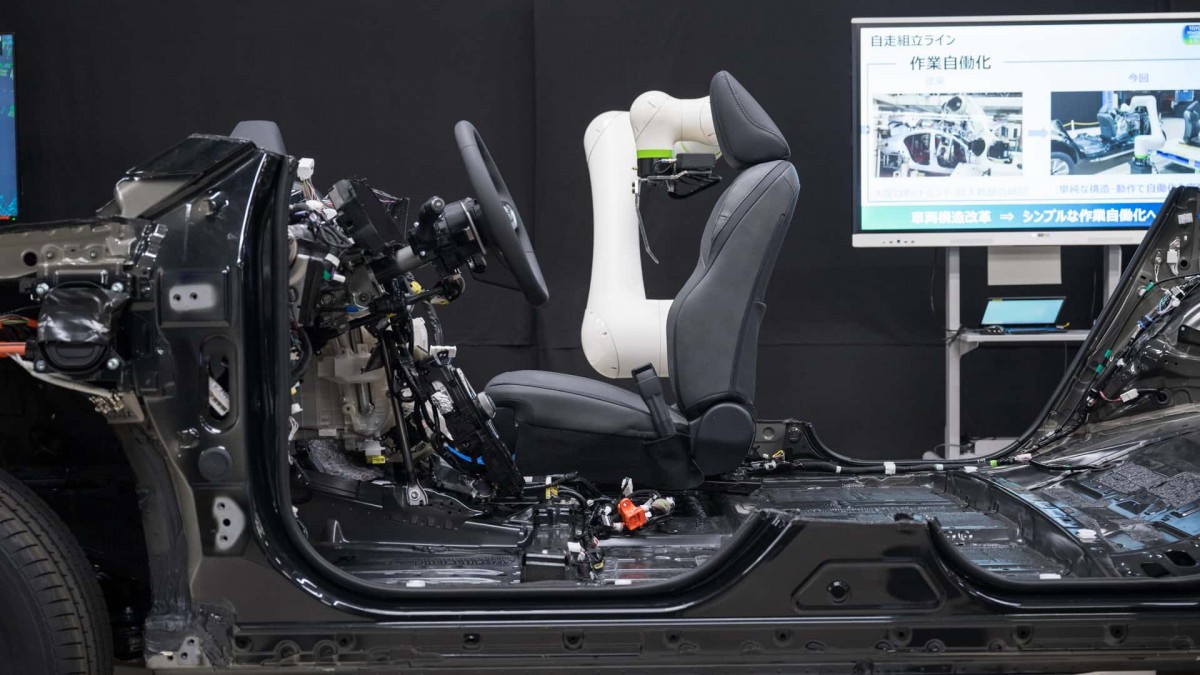

And the ingenuity doesn't stop there. The automaker's modular structure for its upcoming EVs indicates a three-part design covering the front, center, and rear. The purpose? To simplify processes and amp up productivity. Combine this with their "self-propelled conveyance" system, where completed EVs meander through the assembly line at a snail's pace, and you've got a recipe for enhanced layout flexibility.

Did someone mention batteries? Indeed, Toyota did. An image recently surfaced, offering a glimpse into the company's solid-state battery development endeavors. Promising figures float around, such as a staggering 745 miles range and a lightning-fast 10-minute recharge time. Though these numbers sound like a distant dream, Toyota seems confident about bringing these batteries to the market by 2027-2028.

Under the watchful eye of CEO Koji Sato, Toyota has set itself a robust agenda: rolling out 10 new EVs by 2026 and targeting a whopping 1.5 million annual EV sales thereafter. There's even chatter about a three-row electric SUV getting assembled in the US, specifically at their Georgetown, Kentucky plant. Oh, and let's not overlook the cool $2.1 billion they're pouring into their North Carolina battery facility.

Despite all this razzmatazz, there's an elephant in the room. Toyota, for all its grandeur, has yet to capture the EV market in a way some of its competitors have. With BEV sales that pale in comparison to Tesla and even trail behind American heavyweights like Ford and GM, one wonders: can this giant truly pivot and dominate the electric scene? Well, it's Toyota after all, and dismissing it would be foolish.

Reader comments

- nikhil

- r4p

Toyota's new giga-casting technology seems impressive, but let's not forget that Tesla pioneered this approach. Are they just playing catch-up?

Facebook

Twitter

Instagram

RSS

Settings

Log in I forgot my password Sign up